PROFESSIONAL FOR TRUST SINCERITY AND HONESTY FOR FUTURE

KEYPOINT MANAGEMENT SYSTEM MAKES OUR PRODUCTION CONTROL PRACTICABLE

In our keypoint management system, all production procedures are standardized based on enterprise production principles and international standards. And each link has a strict inspection system to ensure all key points regarding the product quality are under controlled. We implement our keyponint management from the following aspects.

We check labels for right materials before production. Generally, we follow the following steps.

Check the labeled materials in the warehouse and mill certifications.

Make sure the materials are in compliance with customers' requirements.

All production will start with sample. we will test the sample in appearance and technical data. When the sample is qualified, normal production can start. As for sample test, we generally test samples from the following aspects:

Surface finish & cleanliness

Surfacefinish

Slight damage of the perforated metal plate by mechanical action during the perforation process cannot be excluded.

When there is a significant impact, the purchaser should negotiate with the manufacturer before placing an order.

SURFACE CLEANLINESS

Perforated metal plates are usually supplied with a light oily film. There should be no excessive seepage of oil after stacking.

Degreased perforated metal plates, e.g. prepared by solvent or steam treatment, may be supplied by agreement. Degreasing is inappropriate for plates of low-carbon steel unless subsequent protection against corrosion is provided.

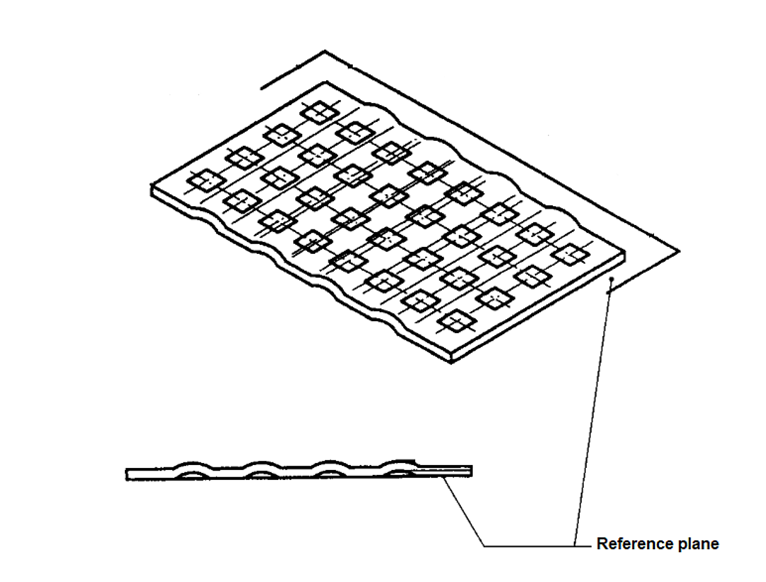

Surface flatness

Each sheet will be flattened twice after punching. It maximally guarantees the perfect flatness of the perforated metal sheets.

All Products should be tested according to GB/T 19360-2003 & ISO 10630 standard.

FF5E14

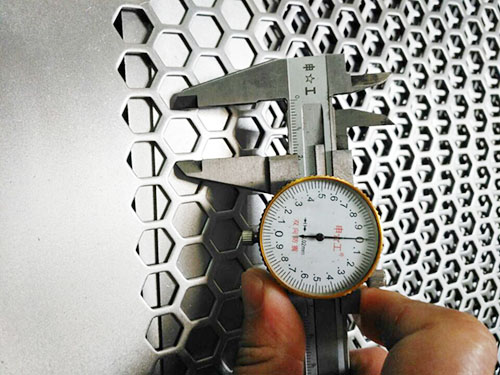

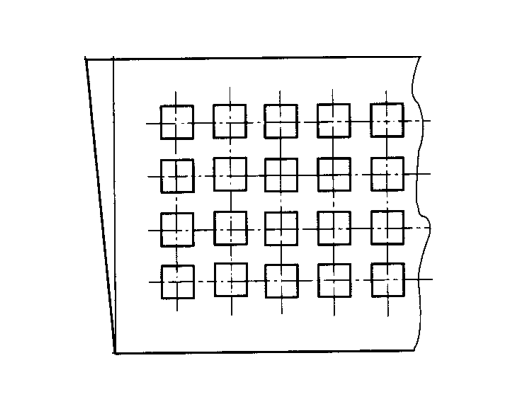

FF5E14Panel/sheet opening size/bars/margins measure

Start mass product,need measure the opening/bars/margins if same with the customer request,if with tolerance.

The tolerance if match the ASTM E674-12,ASTM E454-12,GB/T 19360-2003 standard

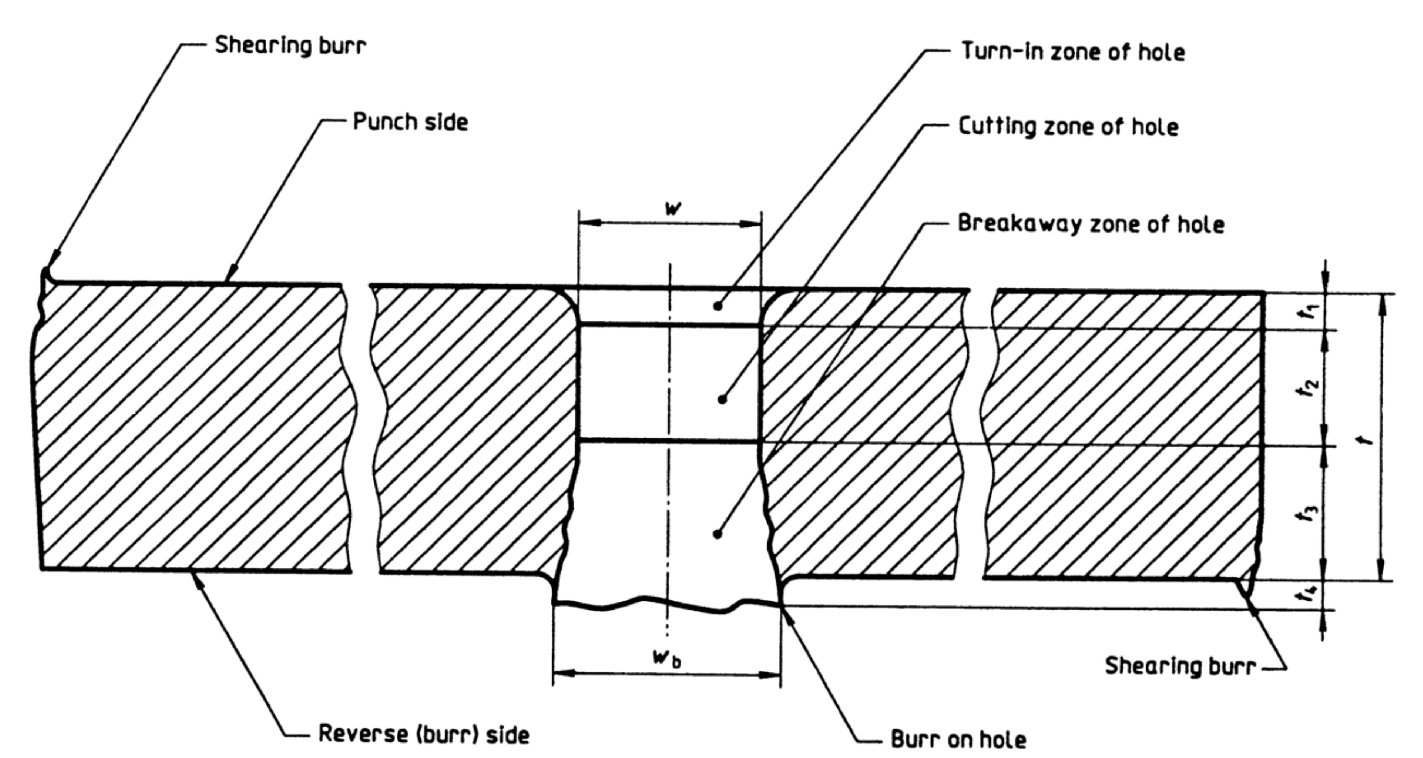

Manufacturing defects

We will supervise the production and do our best to minimize manufacturing defects during production. We must ensure our perforated metal sheets are qualified and free from the following manufacturing defects.

Manufacturing tolerances

We believe that strict inspection ensures high quality. We will debug the machine and strictly control the production process and ensure all products are in compliance with ASTM & ISO standard tolerances.

FF5E14

FF5E14Surface coating & color

SURFACE COATING

We have a fully automatic electrostatic spraying production line to maximally guarantee the coating quality.

SURFACE COLOR

We have standard RAL color card to control and test the product color to minimize the color difference.

For the color,we can as RAL color ,PANTONE color,NCS color,RGB color etc.

What you need is what we serve.

.png)